The safety bits that need to be changed are on the robot.

In the attachment you can find the KUKA ProfiNet manual. There is a description of the different bits that can be read or written to.

I do have a question about this. Why do you want to use PROFIsafe? Do you want to configure your PLC as safety device? Or do you need to add specific safety features or get the current safety state from the robot?

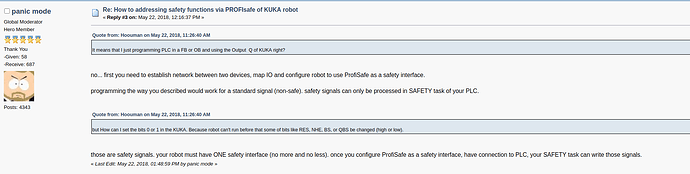

You should give the forum post below a read.

https://www.robot-forum.com/robotforum/kuka-robot-forum/how-to-addressing-safety-functions-via-profisafe-of-kuka-robot/

KUKA_ProfiNet_31_en.pdf (2.2 MB)